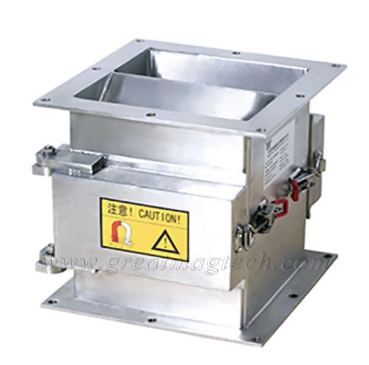

Magnetic plate pipe iron remover is usually composed of stainless steel shell and two or more magnetic plates. The magnetic plate pipe iron remover is mainly used for removing ferromagnetic metal impurities of larger particles with a diameter of 1mm or more, such as screws, nails, springs, iron wires, etc., and is suitable for powdery and granular materials. When the material is passed through the magnetic plate type pipe separator, the material will be diverted to the working area of ??the magnetic plate due to the role of the deflector plate. A strong magnetic field will firmly adsorb the iron impurities in the material to achieve the effect of removing iron, thereby realizing material purification. The purpose of protecting the safe and efficient operation of downstream equipment.

Optional features:

1. Surface treatment: mirror polishing, wire polishing, sandblasting;

2. Shell material: SS304, SS316;

3. Magnetic plate magnetic strength level: 1500Gs, 4000Gs, 8000Gs, 10000Gs;

4. Operating temperature <: 80 °C, 100 °C, 120 °C, 150 °C, 180 °C, 200 °C;

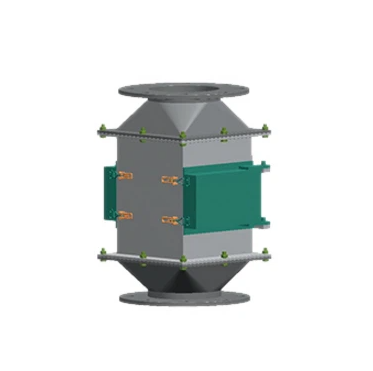

5. Inlet and outlet connections: flanges, flexible connection crimps, straight tubes, etc.

How to clean up:

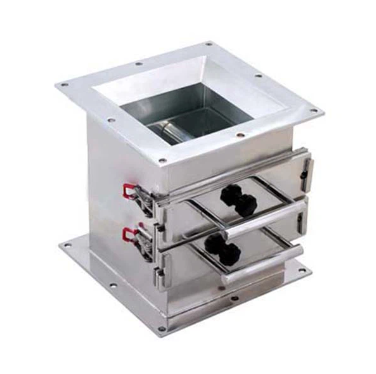

Cleaning frequency: magnetic plate pipe iron remover should be regularly cleaned according to the use of the situation, usually the magnetic plate surface adsorption iron impurity thickness can not be greater than 30mm,

Cleaning steps: Open the door first when cleaning. Use the auxiliary tools such as rag, plastic or stainless steel scraper to clean the iron impurities adsorbed on the surface of the magnetic board. Close the door after cleaning the magnetic board.

The following matters should be noted during the clean-up process:

1. Wear protective gloves to prevent iron impurities from causing damage to the operator’s hands;

2. Use tools such as trays to prevent iron impurities from falling into the interior of the pipeline;

3. When cleaning, ensure that the pipeline in the cleaning area is stopped and no material passes through. For 24 hours operation, double iron separators are recommended (consult our sales staff).

Features:

1. The magnetic plate is mounted on the box in the form of a hinge, and it is disassembled and cleaned.

2. The wedge-shaped partition at the inlet can prevent the materials from bridging and even crack the aggregated material and lead to the strong magnetic plates on both sides, which helps the iron impurities to be fully separated.

3. If rare-earth permanent magnetic plates are used, almost all ferromagnetic objects of all sizes can be firmly absorbed.

4. Special requirements can be customized according to customers.

Application area:

Magnetic plate pipe iron remover can be conveniently installed on a closed production line or processing equipment. It is widely used in food, medicine, tobacco and chemical industry. It removes iron and iron chips from some materials that are easy to clog and block. And other fields.