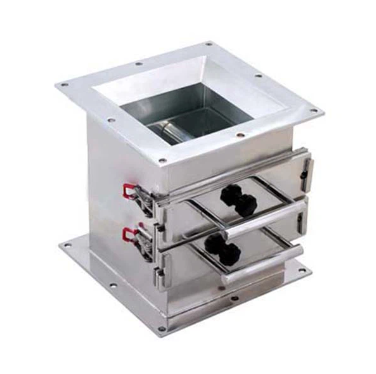

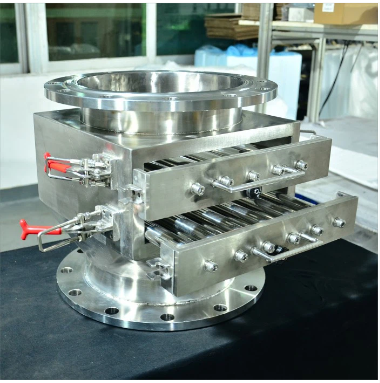

Magnetic Drawn, Grate Magnets in Housing effectively remove ferrous fragments and fines from free-flowing material. They are designed for ferrous metal separation in a wide variety of dry processing applications. Housings are constructed of 304 or 316L stainless steel. Wide stainless steel can be provided on request. Strong magnetic grates inside filter the flow and extract the unwanted ferrous metal. They are widely used in the food industry and the chemical industry. Inside the housing, it can be one layer, two layers, or more layers of high-intensity magnetic grates in frames. To initiate cleaning, the operator pulls two handles to the front of the housing, removing the magnetic drawer from the product flow. As the drawer is pulled out, you can wipe off the accumulated metal from the tubes into a catch box for disposal.

The easy-clean version grate magnets in the housing are designed to simplify the cleaning process to encourage frequent and quick removal of collected tramp metal. Cleaning of the magnets is easily accomplished by removing the tube casing of the grates and sliding out each magnet assembly.

Magnetic Drawers Optional Features

1. The frames and housing material: SS304, SS316, SS316L;

2. The surface finishing: Fine polishing, dull polish, or sandblasting;

3. The magnetic strength grade: 3000Gs, 8000Gs, 10000Gs, 12000Gs;

4. Working temperature grade <: 80, 100, 120, 150, 180, 200 degrees Celsius;

5. Type of mounting: Round or Square, flange or quick-release clamp;

6. Various designs are available: Easy-clean type, one layer, multilayer;

7. Customer designs and specifications can be fulfilled.

Circular Fitting

Circular fitting—Single row version/Circular fitting—Double row version

| Part No. | A=B | C=D | H |  |

| MD-S-S-100 | 100 | 180 | 200 | |

| MD-S-S-150 | 150 | 230 | 200 | |

| MD-S-S-200 | 200 | 280 | 200 | |

| MD-S-S-250 | 250 | 330 | 220 | |

| MD-S-S-300 | 300 | 380 | 220 | |

| MD-S-S-350 | 350 | 430 | 220 | |

| MD-S-S-400 | 400 | 480 | 220 |

All dimensions in mm. Other dimensions can be provided on request

Drawer Magnet for Plastic Processing

Drawer Magnets provide valuable protection for injection molding machines, blow molding machines, and extruders. They are primarily used in plastic progressing to prevent tramp metal damage. These drawer magnets provide economical continuous protection against costly machine downtime for all types of plastic resin processing machinery. Mounted directly on the feed throat of your plastic processing equipment, tramp metal is stopped from flowing into the machine by powerful magnets. Drawer magnets are available in different styles to suit specific application needs.

Part No. Number of magnetic bar Dimension (mm)

| Part No. | Number of the magnetic bars | Dimension (mm) |  |

|||

| A | BxC | D | E | F | ||

| Drawer-100 | 3 | 265 | 100×100 | 165 | 65 | 22 |

| Drawer-150 | 5 | 270 | 150×150 | 216 | 70 | 45 |

| Drawer-200 | 7 | 275 | 200×200 | 267 | 75 | 79 |

| Drawer-250 | 9 | 280 | 250×250 | 317.5 | 80 | 100 |

How To Do Cleaning Drawers Magnets

Drawer Magnets should be cleaned periodically for the most efficient performance. To clean the magnetic tubes, release the latch first and open the door. Remove the grate assemblies one at a time. Remove the tramp metal by hand with cotton gloves or a duster.

Use extreme caution and wear gloves during the process. For any queries or else for placing your orders feel free to contact us now.

Construction

1. Stainless Steel Construction. Mild steel is available on request.

2. Surface processing: Polishing and Painting for your choice.

3. Normally, it is equipped with high-density Ceramic 8 magnets. High-energy Rare-earth magnets are needed when you come across a difficult job.

4. All the magnetic bars are waterproof.