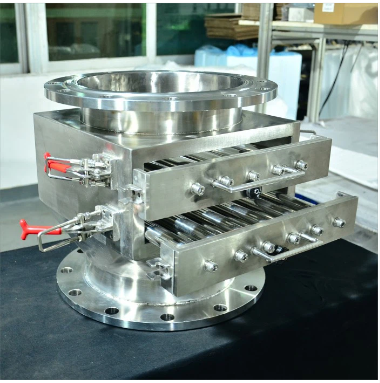

Double-Layered Drawer Magnets

Drawer Magnet is a double-layer or multi-layer grate magnet with a stainless steel housing.

Magnetic drawer separators are suitable for free-flowing products. Generally, they have one or two rows of magnetic bars, staggered one above the other. The bars are located at the center of the product flow. This ensures that the product always passes very close to one or more magnets.

There are many types of magnetic separators, therefore our sales and technical consultants are ready to help you to select and configure a magnetic separator that meets exactly your needs

Construction of Double-Layered Drawer Magnets

Drawer Magnets are mounted on the throat of the molding machine, the tramp metal will be stopped from flowing into the machine by powerful rare earth neodymium magnets to capture and hold ferrous particulates so small that may not be visible to the naked eye.

Multiple staggered rows provide maximum contact area for product flow. As the product flows through the stainless steel housing, it cascades over the staggered rows of magnetic tubes or magnetic bars.

Product features:

– 304 or 316L stainless steel are available for pipeline material which can be fine polished and meet the standard of food or pharmacy industry.

– double-layered/Multi-layered

– Easy-clean type can be selected.

– Different fittings are available to easily connect the Magnetic Liquid Trap into any pipeline.

– The maximum magnetic induction intensity can reach 12000GS for normal types and 10000GS for easy-clean types.

– The standard working temperature can reach 80 ºC and the maximum working temperature can reach

350ºC if needed.

– We also offer customized products

Package:

Our products are all packed in non-magnetic packaging, which can ensure that the products can be transported to your door safely and error-free.

Application:

They are widely used in ceramics, chemicals, plastics, rubber, pigment, mining, food, environmental protection, and other fields. They are used to remove ferromagnetic impurities in dry powder, sheet, granular, and other materials.