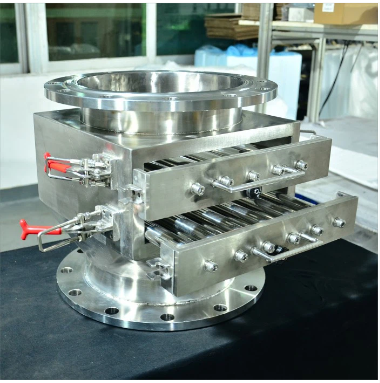

Drawer Magnetic Separator offer unsurpassed levels of contamination removal.

Drawer Magnetic Separator is designed to remove ferromagnetic impurities, weak magnetic iron contaminants, and others in free-flowing, externally-conveyed materials (such as pellets and powders) and other small paramagnetic particles, which can effectively purify the material, improve material quality, and protect the downstream equipment from the damage of the ferrous, to ensure the efficient operation of processing equipment.

Drawer Magnets provide valuable protection for injection molding machines, blow molding machines, and extruders. They are primarily used in plastic progressing to prevent tramp metal damage. These drawer magnets provide economical continuous protection against costly machine downtime for all types of plastic resin processing machinery. Mounted directly on the feed throat of your plastic processing equipment, tramp metal is stopped from flowing into the machine by powerful magnets. Drawer magnets are available in different styles to suit specific application needs.

Drawer Magnets Features

1. The maximum magnetic strength can reach 12000GS for normal (N Style) magnetic drawer and 8000GS for easy cleaning (E Style).

2. Square or round flange of entry is available to suit each customer’s requirement for easy installation.

3. Standard working temperature≤80℃, and maximum working temperature can reach 350℃ as required.

4. The magnetic grid in the drawer with one row or two rows or more rows can be produced according to customers’requirements.

5. 304 or 316L stainless steel are available for pipeline materials.

| Model NO | Dimension(mm) |

Weight(Kg) |

|||

| D | H | A | B | ||

| NR150 | 159 | 286 | 208 | 205 | 20 |

| NR200 | 219 | 286 | 258 | 255 | 28 |

| NR250 | 273 | 286 | 308 | 305 | 33 |

| NR300 | 325 | 286 | 358 | 355 | 43 |

| NR-150 | 159 | 216 | 208 | 205 | 16 |

| NR-200 | 219 | 216 | 258 | 255 | 20 |

| NR-250 | 273 | 216 | 308 | 305 | 24 |

| NR-300 | 325 | 216 | 358 | 355 | 31 |

| Model NO | Dimension(mm) |

Weight(Kg) |

||

| H | A | B | ||

| NS2020 | 270 | 208 | 205 | 16.5 |

| NS2525 | 270 | 258 | 255 | 25.5 |

| NS3030 | 270 | 308 | 305 | 32.5 |

| NS3535 | 270 | 358 | 355 | 39 |

| NS4040 | 270 | 408 | 405 | 50 |

| NS-2020 | 200 | 208 | 205 | 12.5 |

| NS-2525 | 200 | 258 | 255 | 19.5 |

| NS-3030 | 200 | 308 | 305 | 23.2 |

| NS-3535 | 200 | 358 | 355 | 27 |

| NS-4040 | 200 | 408 | 405 | 35.5 |

Application

Magnetic Drawers are widely used in fields of ceramics, chemicals, pharmacy, food, plastic, rubber, dyestuff, mining, and environmental protection, which are designed for removing Ferrum scraps from dry powder, strip, or graininess materials such as sugar, grain, tea, etc.

Magnetic Drawer Package

Our products are all packed in non-magnetic packaging, which can ensure that the products can be transported to your door safely and error-free

How To Do Cleaning Drawers Magnets

Drawer Magnets should be cleaned periodically for the most efficient performance. To clean the magnetic tubes, release the latch first and open the door. Remove the grate assemblies one at a time. Remove the tramp metal by hand with cotton gloves or duster.

Use extreme caution and wear gloves during the process. For any queries or else for placing your orders feel free to contact us now.