Checkweigher is usually used to make sure the product is in standard weight. The checkweighing system is always located in the end of the production line, and Techik can provide customers suitable solutions for the specific products.

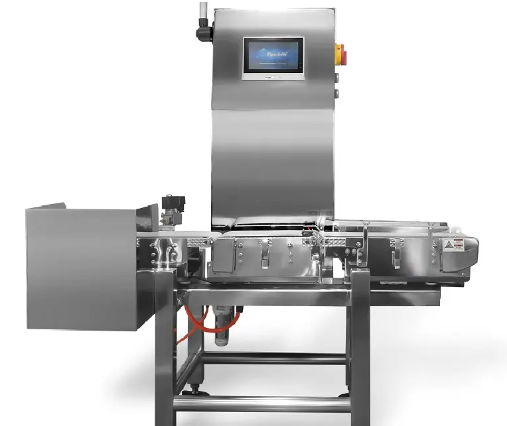

*Checkweigher for Small Packages Introduction:

Techik Checkweigher for Small Packages can be used in various industries including bakery, meat, seafood, snack food, etc. It can accurately reject the underweight or overweight products which are not in compliance with weight standard.

*Checkweigher for Small Packages Advantages:

1.High speed, high sensitivity, high stability dynamic weight checking

2.Buckle design, easy to clean, simple to disassemble

3.7-inch touch screen, user-friendly function

Multi language

Data storage

Large memory capacity

4.Accurate and efficient rejecter system

5.Brief user parameter setting, easy for operation

6.Good environmental adaptability and stability

*Checkweigher for Small Packages Parameter

| Model |

IXL-160 |

IXL-230S |

IXL-230L |

IXL-300 |

IXL-350 |

IXL-400 |

|

| Detecting Range |

5~600g |

10~2000g |

10~2000g |

10~5000g |

10~5000g |

0.2~10kg |

|

| Scale Interval |

0.05g |

0.1g |

0.1g |

0.2g |

0.2g |

1g |

|

| Accuracy(3σ) |

±0.1g |

±0.2g |

±0.2g |

±0.5g |

±0.5g |

±1g |

|

| Max Speed |

250pcs/min |

200pcs/min |

155pcs/min |

120pcs/min |

100pcs/min |

80pcs/min |

|

| Belt Speed |

70m/min |

70m/min |

70m/min |

70m/min |

70m/min |

70m/min |

|

| Weighed Product Size | Width |

150mm |

220mm |

220mm |

290mm |

340mm |

390mm |

| Length |

200mm |

250mm |

350mm |

400mm |

450mm |

500mm |

|

| Weighed Platform Size | Width |

160mm |

230mm |

230mm |

300mm |

350mm |

400mm |

| Length |

280mm |

350mm |

450mm |

500mm |

550mm |

650mm |

|

| Operation Screen |

7” touch screen |

||||||

| Product Storage Quantity |

100 kinds |

||||||

| Segments Number of Sorting |

2/3 |

||||||

| Rejecter Mode |

Rejecter optional |

||||||

| Power Supply |

220V(Optional) |

||||||

| Degree of Protection |

IP54/IP65 |

||||||

| Main Material |

Mirror Polished/Sand blasted |

||||||

*Note:

1.The technical parameter above namely is the result of accuracy by checking only the test sample on the belt. The accuracy would be affected according to the detecting speed and product weight.

2.The detecting speed above will be affected according to the product size to be checked.

3.Requirements for different sizes by customers can be fulfilled.