Magnetic Grate, Grate Magnets description:

The grate magnet has a beautiful appearance, and it is designed to be disassembled and easy to clean. The magnetic strips are reasonably distributed and can provide a high-strength magnetic field to attract small pieces of magnetic metal such as iron powder and iron filings in the flowing materials.

Magnetic Grate Separators also referred to as hopper magnets, magnetic grid, grates in housing, and magnetic grate separators, GME offers custom shapes, sizes, and configurations. Please specify the size of the grate magnet required for your application with your inquiry.

Magnetic grates are designed for product purity for free-flowing materials such as carbon black, drugs, chemicals, cosmetics, food products, plastics, grains, spices, sugar, honey, salt, and minerals. These units are easily installed in any hopper or floor opening, chute or duct.

The Magnetic Grids protect your processing machinery against ferrous impurities. Magnetic filter bars are fixed onto a stainless steel framework, when anything containing iron substances passes through the framework, Iron particles are attracted to the bar magnets by magnetic fields. As a result, your equipment and facilities will be safe and sound, and your products will be safe for consumption.

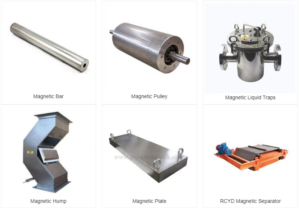

Other Magnetic Separator:

Magnetic separation is the process of separating components of mixtures by using magnets to attract magnetic materials. The process that is used for magnetic separation detaches non-magnetic material from those that are magnetic. Magnetic separators are widely used in mining, the wood industry, ceramics, chemical, food, and other industries.

By carefully calculating the dimensions of the entire system, the resistance to the material flowing through is small and the chance of bridges forming is minimal. GME permanent hopper magnet, grate magnets or magnetic grate with neodymium magnets are suitable for temperatures up to 80°C.

Customized Products: