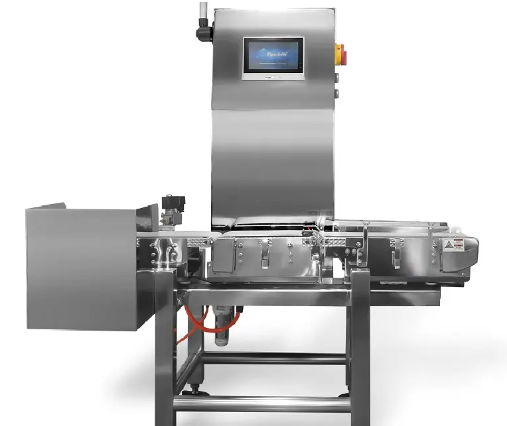

Bulk Product Bulk Food X-ray Inspection System, the flagship product of Techik, is high sensitivity, especially in the detection of organic impurities and small contaminants. Techik Bulk Product Bulk Food X-ray Inspection System receives high recognition in various industries, such as beans, raisins, cashew, garlic slices, peanuts, sunflower seeds, pepper, candy, coffee beans, frozen fruit & vegetables ( frozen cherry, frozen blueberry and etc.), fresh fish and etc. ,

*Product Introduction of Techik Bulk Product Bulk Food X-Ray Inspection System:

It is widely used to inspect product like nuts, grains, corns, raisins, sunflower seeds, beans, frozen fruits etc in pre-packaging detection.

It can find out small stones mixed in product

32/64 air rejecter system which can ensure minimum quantity of waste

It can reach 2-6 tons per hour

*Advantages of Techik Bulk Product Bulk Food X-Ray Inspection System

1. High sensitivity and accuracy

High sensitivity, especially in the detection of organic impurities and small contaminants. Accuracy has been improved by two levels, which can perfectly solve the root cause of customers’ food contaminants complaint.

2. Low energy consumption

High configuration detector can improve detection precision and lower machine power consumption.

3. Upgraded image processing algorithm

High-quality image processing algorithm, the algorithm processing speed is double increased, the detection time of a single product is less than 50 ms, and the accuracy is improved by at least 1 level to achieve high-precision detection.

4. Modularized structure design

The updating structure design with modularization is won great appraise from Techik clients.

The modular structure design makes one part suitable for various models, which can improve the production efficiency by 30% – 40%. The product is highly integrated which makes the maintenance more convenient and greatly reduces the operation and maintenance costs of customers, such as conveyor belt and arm device.

5. High level hygienic design

The bulk X-ray is equipped with soft flanges to prevent materials from falling into the belt gap, such as rice, red beans and other granular food, which can not only reduce food consumption, but also reduce the trouble of machine cleaning, so as to achieve a higher level of sanitary design.

*Parameter

| Model |

TXR-4080P |

TXR-4080GP |

TXR6080SGP (Second generation) |

| X-ray Tube |

MAX. 80kV, 210W |

MAX. 80kV, 350W |

MAX. 80kV, 210W |

| Inspection Width |

400mm(MAX) |

400mm |

600mm(MAX) |

| Inspection Height |

100mm(MAX) |

100mm |

100mm(MAX) |

| Best Inspection Sensitivity |

Stainless steel ballΦ0.3mm Stainless steel wireΦ0.2*2mm Glass/Ceramic:1.0mm |

Stainless steel ballΦ0.3mm Stainless steel wireΦ0.2*2mm Glass/Ceramic:1.0mm |

Stainless steel ballΦ0.6mm Stainless steel wireΦ0.4*2mm Glass/Ceramic:1.5mm |

| Conveyor Speed |

10-60m/min |

10-120m/min |

120m/min |

| Operation System |

Windows XP |

||

| IP Rate |

IP66 (Under belt) |

||

| Working Environment |

Temperature: 0~40℃ |

Temperature: -10~40℃ |

Temperature: 0~40℃ |

|

Humidity:30~90% no dew |

|||

| X-ray Leakage |

< 1 μSv/h (CE Standard) |

||

| Cooling Method |

Air conditioned cooling |

||

| Rejecter Mode |

32 tunnel air jet rejecter or 4/2/1 channels flap rejecter |

48 tunnel air jet rejecter or 4/2/1 channels flap rejecter |

72 tunnel air jet rejecter |

| Shape Select |

No |

Yes |

Yes |

| Power Supply |

1.5kVA |

||

| Surface Treatment |

Mirror polish Sand blasting |

Mirror polish Sand blasting |

Mirror polish Sand blasting |

| Main Material |

SUS304 |

||