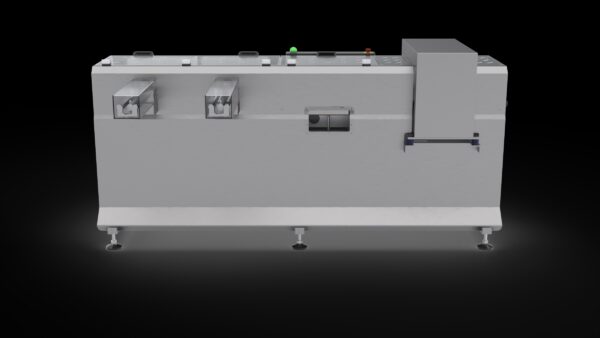

The Raptor is a highly accurate, fully integrated checkweighing and metal detection combination system designed explicitly for high-care food production environments.

The Raptor Combination System can be used at any stage in your process to safely, reliably, and accurately inspect 100% of your products. Multiple end-of-line inspection processes can be carried out and controlled in one highly compact system when paired with an industry-leading Stealth or Interceptor metal detector.

Key Features

- Heavy duty IP65 grade equipment. Robust precision-made lift-out conveyors. No tools. No fuss.

- Available kicker, air-blast and other reject configurations accurately remove non-conforming weights and metal contaminants from the production flow while minimizing product giveaway and protecting brand integrity

- A simple HMI interface ensures user-friendly operation and enhances process efficiencies offering single-point control for both metal detection and checkweighing

- The hygienic design supports sanitation processes with easy clean, sloped surfaces to promote water runoff and speed up drying time

- Belt Widths include 200mm, 300mm, 400mm

- Line Height includes 800mm +/-35mm

- Weight Capacity up to 8kg

- Product Lengths up to 430mm