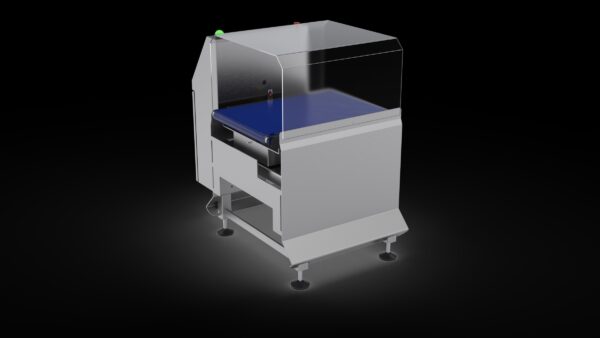

The Raptor XL is a highly accurate, fully integrated caseweighing system specifically designed to suit any large bag or case application.

The Raptor XL is employed to verify the weight of each product within tolerances or using another weighing system. It was designed, engineered, and constructed to the highest care/food grade engineering standards. Available modular reject stations accurately remove non-conforming packs from production flow.

Key Features

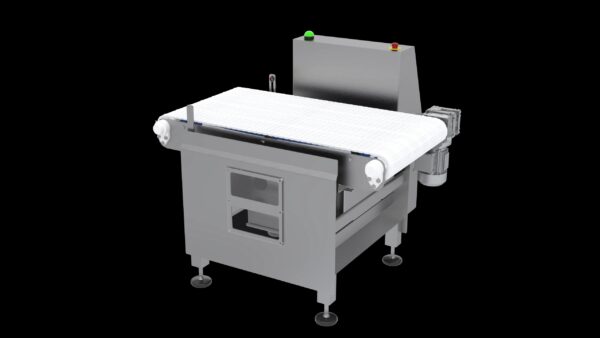

- Heavy duty IP65 protection. Robust, precision-made lift-out conveyor. No tools. No fuss.

- Available in Large Bag configuration for longer packs

- Available modular reject stations allow for flexible integration into existing and new production lines. Available rejects include, but are not limited to belt-stop-alarm, heavy-duty kicker, overhead sweep

- Intuitively integrated with other Fortress metal detection conveyors for a single-point HMI control

- A simple HMI interface ensures user-friendly operation and enhances process efficiencies. The latest generation capacitive industrial touchscreen displays important data and reduces training time

- The hygienic design supports sanitation processes with easy clean, sloped surfaces to promote water runoff and speed up drying time

- Intelligent conveyor design allows for complete removal and disassembly of conveyor components for maintenance access and cleaning in seconds on select systems

- Built-in data collection software with USB data transfer, OPC-UA, and Ethernet/IP facilities (optional) allows for ease of production performance tracking and improvement of operational efficiency

- Belt Widths include 500mm & 600mm

- Line Height includes 800mm +/-35mm

- Weight Capacity includes Regular: up to 25kg, and Heavy-Duty: Up to 50kg